Computerised Maintenance Management System

Plan, Prioritize, Automate & simplify your Maintenance.

What is Computerised Maintenance Management System?

CMMS stands for Computerized Maintenance Management System. It is a software solution that helps organizations manage and streamline their maintenance operations. CMMS is used to organize, track, and manage maintenance activities, including the scheduling of maintenance tasks, tracking of equipment and asset maintenance history, managing work orders, and optimizing maintenance processes.

Implementing a CMMS can lead to increased efficiency, reduced downtime, improved asset reliability, and better utilization of resources in maintenance operations. It is commonly used in industries such as manufacturing, healthcare, facilities management, and transportation, among others.

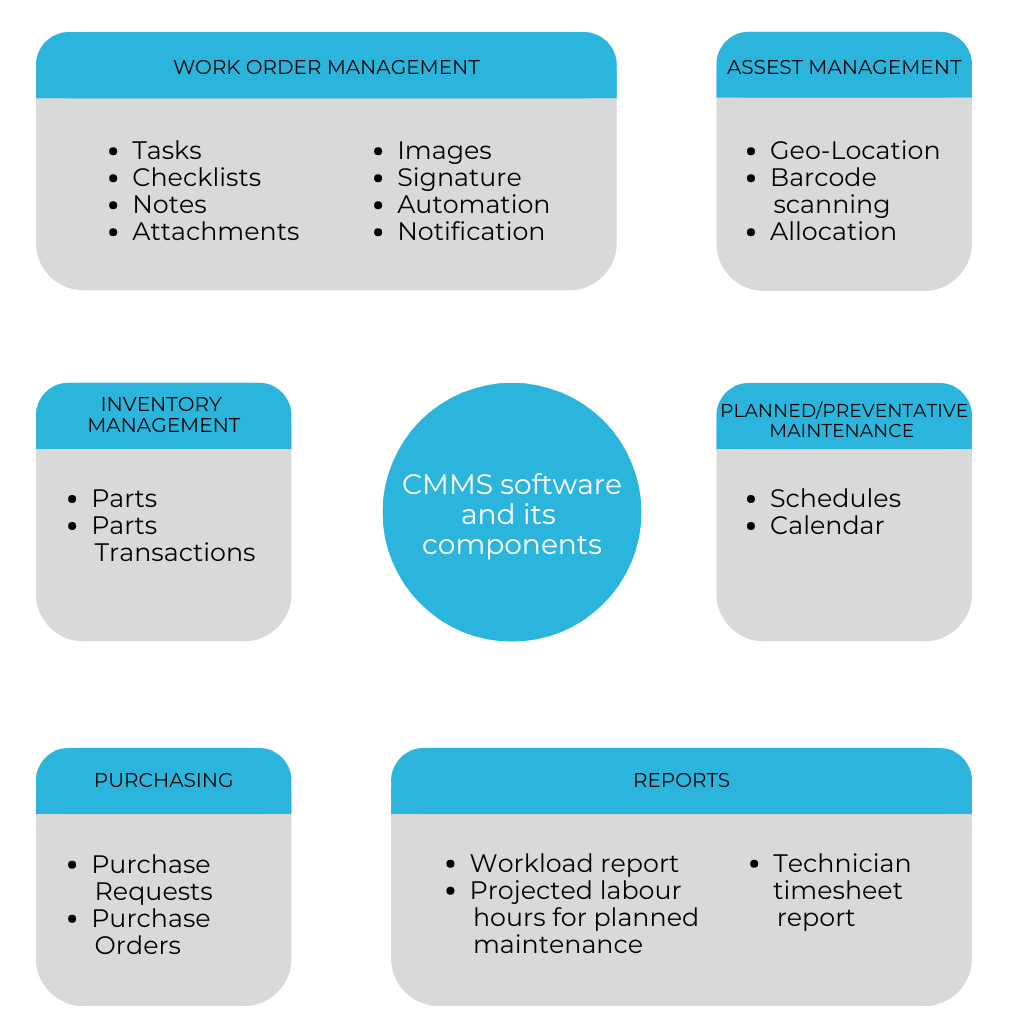

CMMS software & It’s components

Asset Management

Track and manage details such as maintenance history, location and specifications about equipment, machinery and other assets.

Reporting & Analysis

Present maintenance work orders data in an organized manner to help you measure KPIs, analyze time and cost resources, and measure effectiveness and productivity.

Preventative Maintenance

Schedule and automate routine maintenance tasks to prevent equipment breakdowns and extend the lifespan of assets.

Mobile

access

Access the CMMS system through mobile devices, enabling field technicians to update information in real-time.

CMMS can help your business manage its

maintenance – find out more here

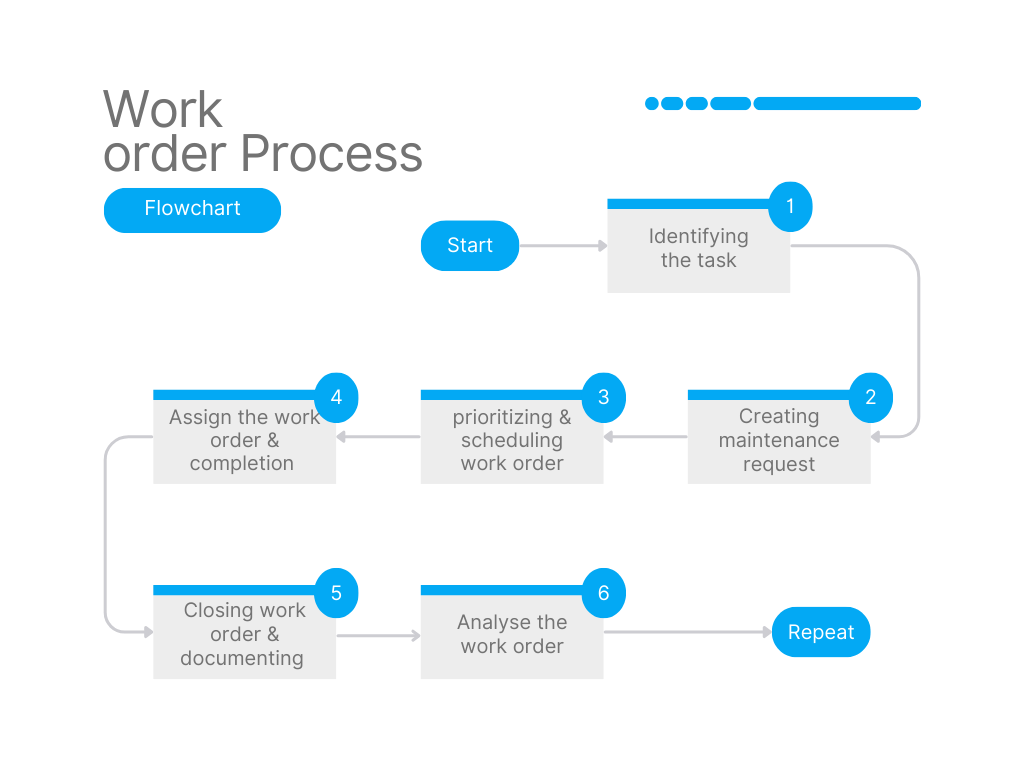

What is a Work Order Process?

A work order process flow can differ based on an organization’s specific procedures and requirements, but here is a generalized outline that represents the common steps in a typical work order process.

Where is CMMS used?

Computerized Maintenance Management System is used in various industries and sectors to streamline and optimize maintenance processes. Some of the prominent sectors where CMMS is commonly used include: